Chapter 5. System configuration

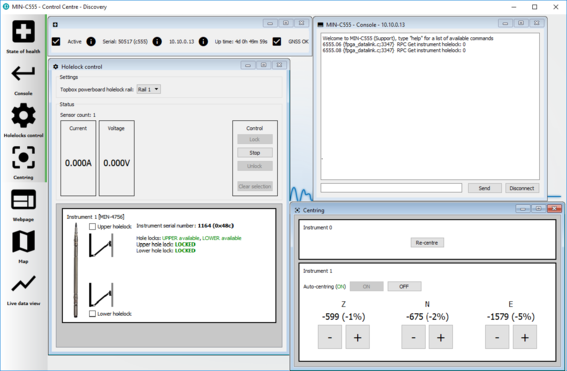

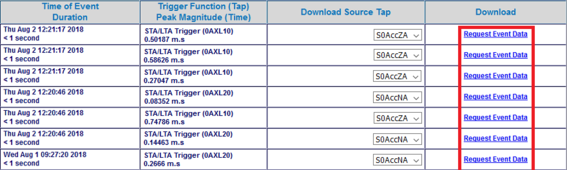

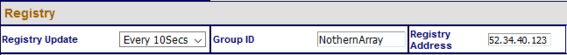

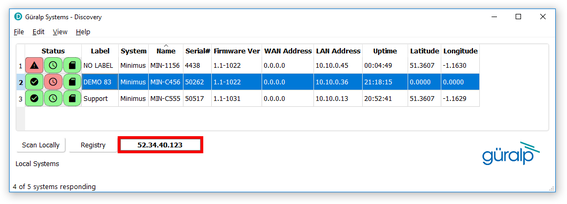

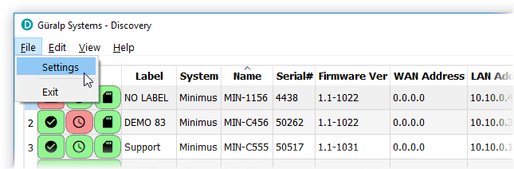

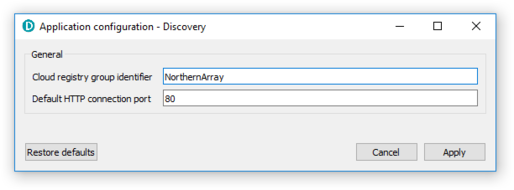

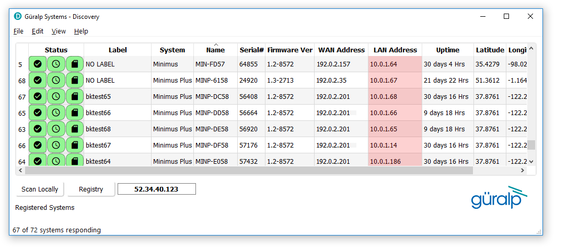

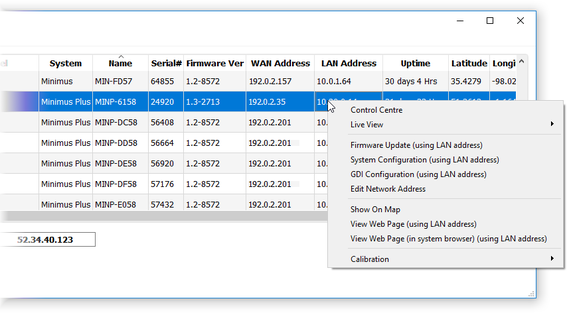

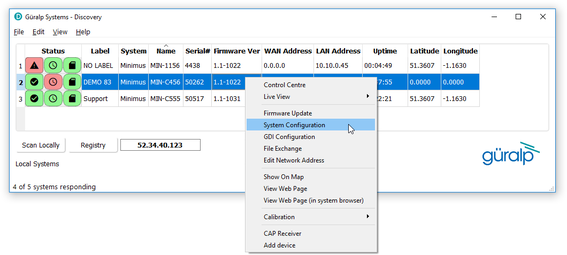

System configuration, control and configuration tools are available by selecting an instrument in Discovery, right-clicking its entry and selecting “View Web Page”. Alternatively, the web interface can be viewed by navigating to the LAN or WAN address of the instrument from any common web browser.

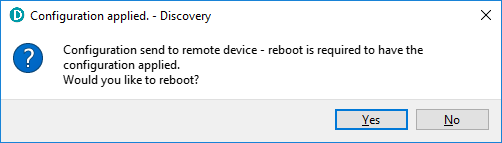

Note: Some changes in the settings require a system reboot to be applied. This is notified on the top right of the Minimus web page with the message Reboot Required . It is suggested to perform all the modifications and reboot the Minimus when the configuration is completed clicking on any of the  buttons.

buttons.

5.1 Web Page login

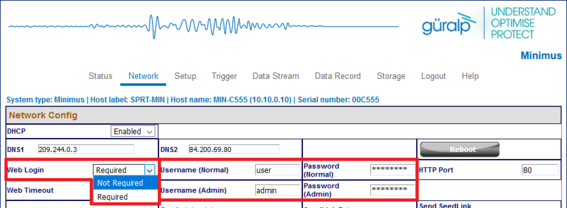

The web interface can be protected by username and password. There are two levels of access to the web page: normal user and administrator.

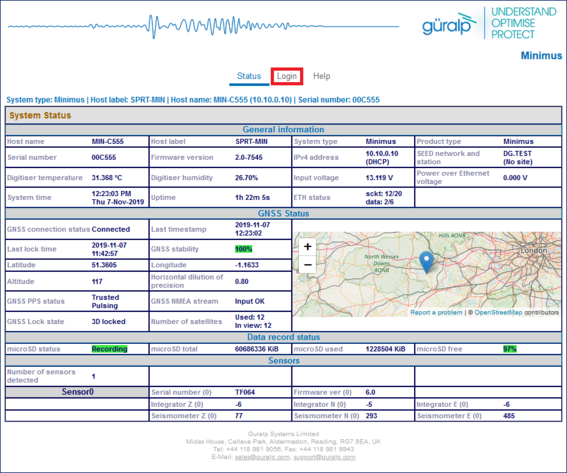

If the login is required, the web interface will initially show a status display only.

Clicking on “Login” opens allows to type in the user-name and password to access the content of the web page.

Logging in with normal user account unlocks only basics configuration and control features in order to prevent any advanced settings to be modified. The default user-name for normal user login is user and password of user.

Logging in with the administrator account unlocks all the configuration and control features available in the Minimus web page. The default user-name for administrator user login is admin and password of admin.

Once logged in, the “Web Login” drop-down menu in the Network tab allows to disable the request of login every time the web page is accessed. The user-name and password for both normal user and administrator login are configurable in the “Network” tab.

5.2 System status

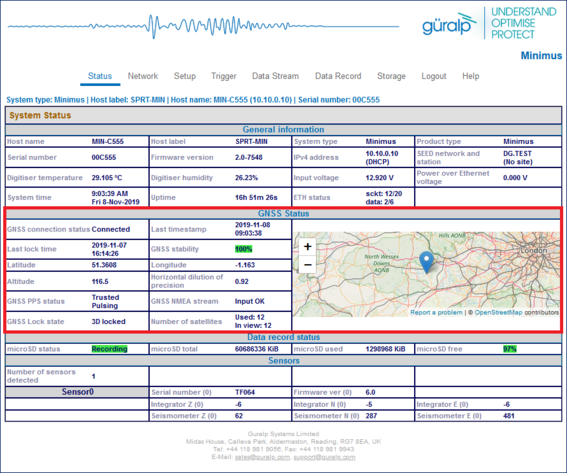

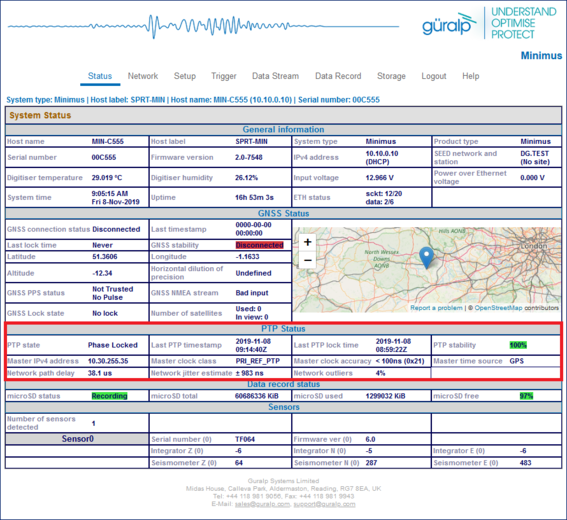

The “Status” tab of the web browser interface provides state-of-health information about the Minimus and connected instruments. These parameters are described as follows:

Host name: the serial number and model of the device;

Host label: the customisable name of the Minimus system;

System type: the name of the connected digitiser, e.g. “Minimus”;

Product type: the type of the connected digitiser, e.g. “Minimus”;

Serial number: the serial number of the Minimus;

Firmware version: the DIG firmware version running on the Minimus;

IPv4 address: the static or Dynamic LAN I.P. address of the Minimus;

SEED network and station: Network and Station SEED codes of the Minimus;

Digitiser temperature, humidity, Input voltage and PoE voltage (⨹ Minimus+ only): the internal temperature and humidity of the Minimus; input voltage supplied and optional PoE voltage (⨹ Minimus+ only) supplied to the Minimus;

System time: the current internal system date and time;

Uptime: the time the Minimus has been running since the last reboot;

ETH status: the number of total active TCP connection in use and connection used for data transmission;

GNSS status, last GNSS time-stamp, last GNSS lock time since significant timing drift or re-boot, GNSS stability of the lock, horizontal dilution of precision (based on satellite coverage), GNSS PPS status, GNSS NMEA stream, GNSS lock state (2-D or 3-D), number of satellites used and in view;

Latitude, longitude and altitude of the system, as provided by the GNSS receiver;

PTP state, last PTP time-stamp, last PTP lock time since significant timing drift or re-boot, PTP stability in time accuracy, master IPv4 address (I.P. address of the PTP master), master clock class and accuracy, master time source, network path delay, network jitter estimate (quality indicator in ns), network outliers;

MicroSD card recording status, total storage capacity, used storage space and available storage space;

Number of instruments connected; and

Real-time sensor values from the connected instruments.

5.3 Station meta-data

Discovery provides a number of flexible station meta-data inputs. These are accessible from the “Setup” tab of the instrument’s web page.

“Label” and “Site Name” are used in Discovery only and appears in the list of instruments in the main window.

“Station Name”, “Network Code” are all standard meta-data header values used by the miniSEED file format, which will be included in locally-stored miniSEED files (see section 8).

5.4 Network configuration

5.4.1 I.P. address and gateway

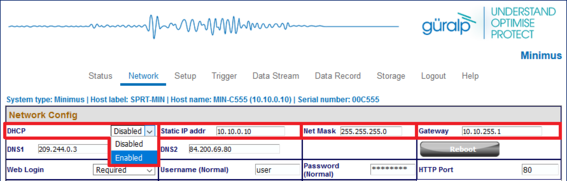

By default, the Minimus uses DHCP (Dynamic Host Configuration Protocol) to acquire its network configuration but static addressing can be used if required.

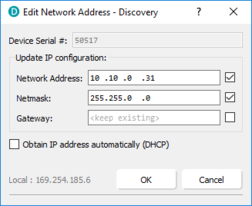

To configure static addressing, visit the “Network” tab of the instrument’s web page and, under “DHCP”, change the mode from “Enabled” to “Disabled” in the drop-down menu. In this mode, it is possible to specify the I.P. address, the Netmask and the address of the Gateway (default router), as shown:

Before any changes made here will take effect, the Minimus must be re-booted. To do this, click the  button on the “Data Record” tab.

button on the “Data Record” tab.

Note: By default, the static I.P. address assigned to each Minimus is unique and derived from the specific serial number of the device. These addresses are in the default network for link-local (APIPA) addresses: 169.254.0.0/16 (in CIDR notation).

The first two octets of the address, therefore, are always 169.254. The third octet is the equal to the last two characters of the serial number interpreted as a hexadecimal number and then converted into base 10. The forth octet is the equal to the next-to-last two digits of the serial number, also converted from hexadecimal into base 10.

For example, if the serial number of the Minimus is MIN-C555, the preassigned Static I.P. address will be 169.254.85.197, where

MIN-C555 ⇒ "55" ⇒ (55)16. = (85)10 ⇒ 85 and

MIN-C555 ⇒ "C5" ⇒ (C5)16 = (197)10 ⇒ 197

Network settings are also available in Discovery by right-clicking on the Minimus' entry in Discovery's main window and selecting “Edit Network Address”.

5.4.2 NTP (Network Timing Protocol) configuration

Note: Network Timing Protocol (NTP) is only used for setting the system's internal clock at boot-up, it is not used for sample timing. See section 5.10 for details about synchronising the sample clock.

However: if neither GNSS nor PTP are available but NTP is locked and the sample clock's time is more than five seconds different from NTP's time, the sample clock will be adjusted (in a step-change) to NTP time.

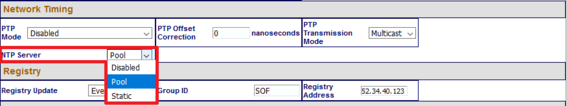

By default, the NTP server option (located under the “Setup” tab of the instrument’s web page) is set to “Pool” which uses the virtual server pool pool.ntp.org. This accesses a dynamic collection of networked computers that voluntarily provide moderately accurate time via the NTP to clients worldwide.

Alternatively, it is possible to specify the I.P. address of your preferred NTP server. To do this, select the “Static” option from the “NTP server” drop-down menu, which activates the “NTP IP Addr” setting, and enter the I.P. address of your NTP server here.

5.5 GDI push (auto-connection)

A Minimus normally acts as a GDI server, where a client initiates a connection in order to pull data from it. This is the mechanism used when the GDI viewer in Discovery is launched.

The "GDI auto-connection" feature enables the Minimus to establish outgoing network connections in order to push data to one or more remote clients, such as Platinum systems or an Earthworm system running the gdi2ew plug-in.

To configure an auto-connection, type either the I.P. address or the host-name of the target client, a colon (':') and the port number (e.g. 192.0.2.91:1566 or affinity10.example.com:1566), into any of the connection fields in the “Network” tab of the web page.

When auto-connection from a Minimus to a host is configured, the Minimus will attempt to open a connection to the host. If it fails, it will re-try every 60 seconds. A suitably configured host will accept the connection and the Minimus will then negotiate a link and start streaming data.

If the connection drops, the Minimus will attempt every 60 seconds to reconnect.

Note: The default port number for a GDI-link receiver is 1566. Push servers will normally connect to this port. The default port number for a GDI-link transmitter is 1565. Receivers wishing to pull data will normally connect to this port. See Chapter 9 for a list of the network ports used by the Minimus.

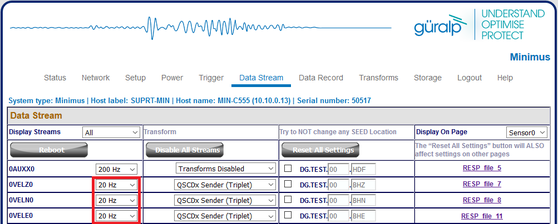

5.6 QSCD

The Minimus can push data in QSCD format (Quick Seismic Characteristic Data) to one or more clients, using outgoing network connections.

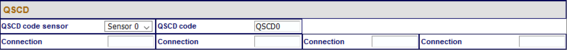

To configure a connection, locate the QSCD section of the Network tab of the web page, as shown below. Type either the I.P. address or the host-name of the target client into any of the “Server” fields. This will push data using UDP port 9000, which is the default. If you wish to use a different port number, add a colon (':') and the port number to the end of the specification. For example, 192.0.2.91:9876 or qscd.server.com:9876.

The Minimus does not automatically send all data when using the QSCD protocol. Channels to be transmitted must be selected (in Z/N/E triplets) and each channel passed through a QSCD transform. See Section 5.15.12 for details on how to configure this transform.

Use the “QSCD code sensor” drop-down menu to select the sensor and assign the desired QSCD code.

5.7 Data storage

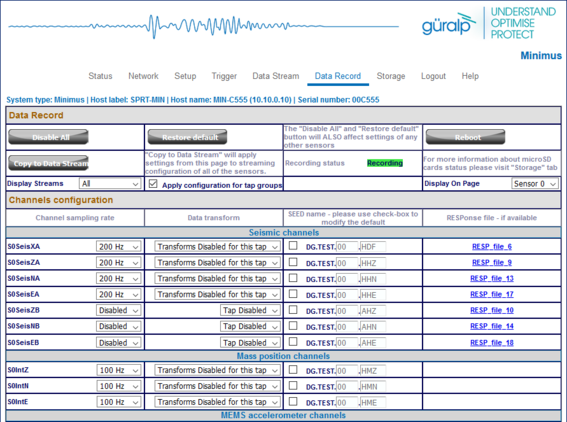

The main panel of the "Data Record" tab in the web interface is shown here:

This page allows to configure the recording channels for each of the connected instruments and sensors internal to the Minimus.

The names and contents of each channel are described in Section 8.

Note: When changing a setting in the Minimus web page, ensure that you wait until the page refreshes before changing another setting. This allows time for the previous change to take effect.

The drop-down box at the top-left of the page named “Display Streams” filters out visible channels among All, Enabled and Disabled. The option “Apply configuration for tap groups” automatically apply the same configuration to three streams that belong to the same tap, e.g. S0SeisZA, S0SeisNA, S0SeisEA. The drop-down box at the top-right of the page named “Display On Page” allows to move from different instruments, e.g. Sensor 1.

The page is divided in four columns:

in the left-most column, drop-down boxes are available for each channel to either select a sample rate or to exclude the channel from streaming (by selecting the “Disabled” option). All streaming can be stopped by clicking the

button. The same configuration can be applied to real-time transmission channels by clicking the

button. The same configuration can be applied to real-time transmission channels by clicking the  button. The default channel configuration can be applied by clicking the

button. The default channel configuration can be applied by clicking the  button.

button.in second column from the left, drop-down boxes are available for each channel to enable/disable transforms and, once transform is enabled, to select the transform to apply (see Section 5.15);

in third column from left, Location and Channel SEED codes can be configured. Cells are greyed out by default (default values applied) and they can be edited by clicking on the check-box;

in most-right column contains links to the RESP files associated to each of the seismic channels (see Section 5.12.5).

Upon changing the sample rate, enabling a transform or changing Location and Channels codes, the Minimus will need to be restarted for the changes to come into effect; this can be done by pressing the  button.

button.

During the reboot, the LEDs will flash, displaying the starting-up sequence (see Section 3.1.1) and the instrument web page will display the following screen.

Once the Minimus has successfully restarted, the full web browser display and controls will be available for use again.

5.8 Storage

5.8.1 Recording status

MicroSD cards need to be specifically formatted to operate with the Minimus. The cards shipped with the Minimus and with Radian systems are supplied pre-formatted.

Data are stored on the microSD cards in miniSEED format. Each channel is saved as a series of 128 MiB files. Instrument and station meta-data (e.g. instrument response, coordinates, compression type etc.) are stored in "Dataless SEED" format.

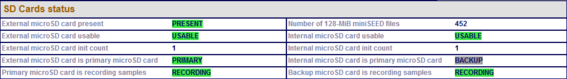

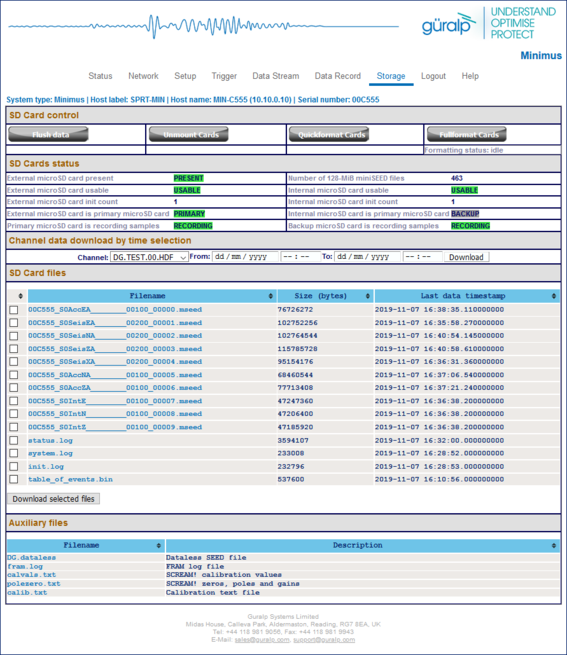

The MicroSD card and data recording status can be monitored in the upper panel of the “Storage” tab.

The left-hand column provides details of the external (primary, removable) microSD card and the right-hand column shows the status of the internal (backup, fixed) card.

Sections of this panel indicate the status of the following:

Whether a card is inserted;

Whether an inserted card is usable (i.e. correctly formatted); and

Whether the card is recording data.

Note: If the recording status of the cards is marked NOT RECORDING, clicking on  or

or  may solve the issue. Note that the quick format simply moves the write-pointer to the beginning of the recording space, hence overwriting any existing data. The full format, in contrast, erases all the existing data (and can take several hours).

may solve the issue. Note that the quick format simply moves the write-pointer to the beginning of the recording space, hence overwriting any existing data. The full format, in contrast, erases all the existing data (and can take several hours).

5.8.2 MicroSD card re-formatting

The card re-formatting process fills the card with 128 MiB files containing zeros. Each file is given a temporary, place-holder name. When data are written, these files are renamed and then over-written with data.

There are two methods for card reformatting: “Quick format” and “Full format”. The quick format mode should be used for pre-deployment tests (e.g. stomp/huddle tests) to ensure that the instruments are operating properly. This mode simply marks the existing files as empty without deleting their contents. Full formatting should be used prior to a long-term deployment to ensure that all headers are included and files are fully clean before writing.

The formatting process formats both fixed and removable cards, sequentially.

Note: A series of tests separated only by quick formats can leave some files with residual data in them. This is not normally a problem because a deployment will typically create data-sets longer than any test, over-writing any data remaining from the tests. The miniSEED extractor utility described in section 5.9.3.1 can be used to remove the residual data if they cause any problems.

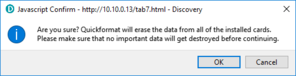

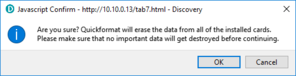

5.8.2.1 Quick format

Ensure that the external microSD card is correctly inserted. Click the  button in the “Storage” tab: a dialogue box will appear to confirm the formatting operation – click on

button in the “Storage” tab: a dialogue box will appear to confirm the formatting operation – click on  button to continue.

button to continue.

The instrument web page will refresh and return to the “Status” tab. The reformatting operation is now complete.

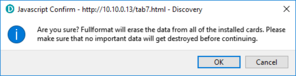

5.8.2.2 Full format

Ensure the external microSD card is correctly inserted. Click the  button in the “Storage” tab and a dialogue box will appear to confirm the formatting operation – click on

button in the “Storage” tab and a dialogue box will appear to confirm the formatting operation – click on  button to continue.

button to continue.

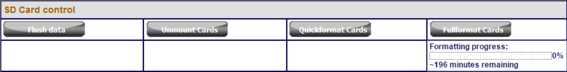

The process takes several hours: check the status countdown indicators on the top-right of “Storage” tab.

Caution: Do not remove or insert the external microSD card while formatting is taking place.

5.8.3 MicroSD card data flushing and unmounting

The  button flushes data still in the buffer into the microSD card storage. Perform a flushing before downloading data from the Storage tab (see Section 5.8.4) or event table (see Section 5.16.5).

button flushes data still in the buffer into the microSD card storage. Perform a flushing before downloading data from the Storage tab (see Section 5.8.4) or event table (see Section 5.16.5).

The  button flushes the data from the buffers into the microSD cards and interrupts the recording. The recording restarts if a new card is inserted in the slot or if a quick-format (or full-format) is performed.

button flushes the data from the buffers into the microSD cards and interrupts the recording. The recording restarts if a new card is inserted in the slot or if a quick-format (or full-format) is performed.

5.8.4 Downloading recorded data

The “Storage” tab of the web browser interface displays the miniSEED files stored on the microSD card:

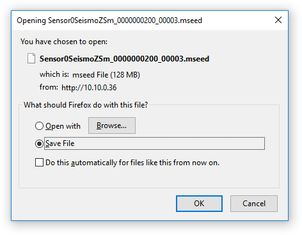

Clicking on the file from the list automatically starts a download using your browser's standard mechanism:

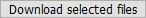

Multiple files can be downloaded simultaneously by ticking the boxes on the left of each link and clicking on  button.

button.

The microSD cards are formatted with empty files which are filled with data as they become available. The file-names are also changed when the files are written to. Until they are written to, they are marked as “hidden” files, so that it is easier to see how many files contain data when looking at the contents of the card.

5.8.5 Downloading data for specific time-intervals

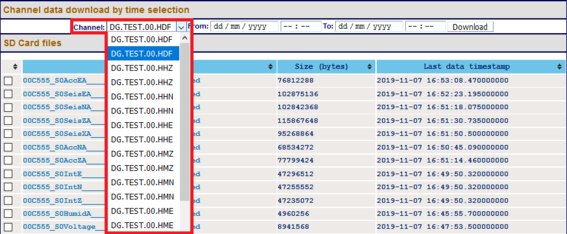

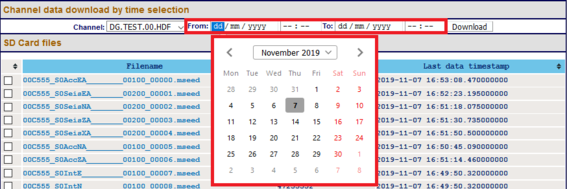

Data for a single stream spanning a specific time-interval can be downloaded from the Storage page of the web interface. To do this, start by selecting the desired stream from the drop-down menu:

… then select the start and end dates and times using the pop-up calendars:

Lastly, click the  download button to initiate a file transfer using your browser's standard mechanism.

download button to initiate a file transfer using your browser's standard mechanism.

Note: The pop-up calendars are not supported by Discovery's built-in browser. The required dates can simply be typed in or the entire operation can be performed in an external web browser.

5.8.6 Bulk data extraction

To view files saved on the external microSD card, remove the card, as described in Section 3.1.3. Insert the card into a microSD card reader (external or in-built) on your PC/laptop. Within a few seconds, the card should appear as a removable disk/drive.

A microSD card formatted for the Minimus contains many "hidden" files. They are created at format time with no contents and then renamed, unhidden and filled with data as required.

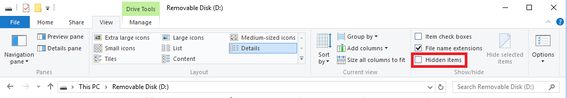

When viewing files in Windows Explorer, it may be helpful to configure your system so that "hidden" files are not shown. In Windows 10, this can be done by clearing the “Hidden items” check-box within the ribbon of Windows Explorer.

5.8.7 The contents of the microSD card

The root directory of the disk contains seven items:

a file named init.log. This “write-once” file contains the first 32 MiB of system log information since the card was last formatted.

a file named system.log. This “re-use” file contains the last 64 MiB of the system log;

a file named status.log. This “re-use” file contains the last 32 MiB of damps of system state of health information. A new dump is generated every 20 minutes.

a disk image file which Güralp technical support may ask you to use if you have problems with the card;

a file named table_of_events.bin. This is not human readable: it is used by the Seismic Events Table in the “Trigger” tab

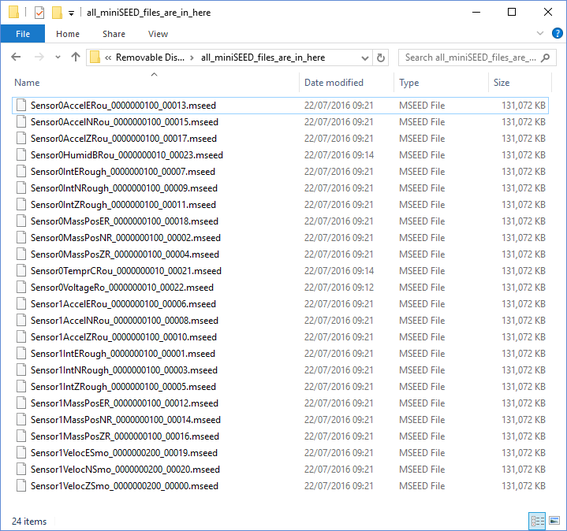

a directory named all_miniSEED_files_are_in_here. Within this directory, there will be a miniSEED file for each recording channel. The file-name prefix is the same as the channel name description given in the “Data Record” tab. Each file is 128 MiB in size.

The typical contents of the all_miniSEED_files_are_in_here directory looks like this:

The file-name consists of four components:

The stream name, truncated to 16 characters - see Section 8 for a full list of these;

The sample rate (in samples per second) as a ten-digit decimal number, left-padded with zeros;

A number which functions as a counter to ensure unique file-names for all files. Each time a file is created, this number is incremented so that the next file to be created will use the next value; and

The .mseed extension which identifies this as a miniSEED file.

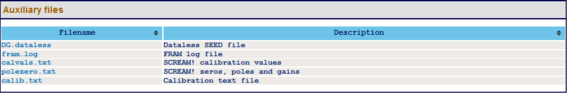

The "Storage" tab also shows links to five auxiliary files, which are either saved in the Minimus' flash RAM or are dynamically generated:

network.DATALESS : This is a dataless SEED volume that contains meta-data including instrument responses, coordinates, compression type and more. It is generated from the RESP files for each channel. The first component of the file name depends on the the two-character Network code defined in the "Setup" tab. If, for example, this is GU, the file is called GU.DATALESS.

fram.log : this is the FRAM log file. It is stored in FRAM.

calvals.txt : this file contains calibration information in a format compatible with the Scream software package. It is dynamically generated.

calib.txt - this file contains calibration information with poles, zeros etc expressed in hexadecimal notation. It is stored in FRAM.

polezero.txt : this file contains definitions of frequency responses in a format compatible with the Scream software application. It is dynamically generated.

5.8.8 Request data from microSD card

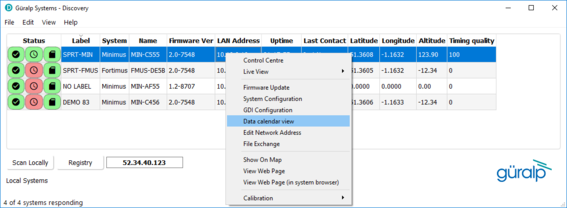

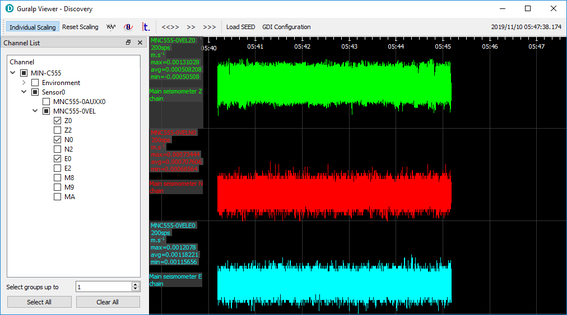

Discovery can be used as viewer of seismic data locally recorded in the microSD card of a Minimus.

Select the Minimus of interested, right-click and choose “Data calendar view” to open the complete list of streams.

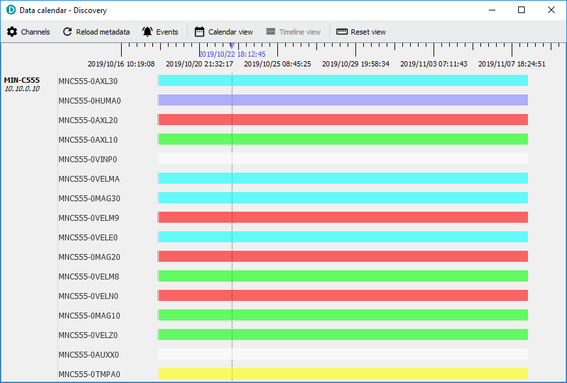

The calendar shows two weeks of data preceding the time when the request is sent and it includes all the available channels recorded in the microSD card, distinct by stream name and predefined colour.

Note: Any gap in the calendar view is symptom of a gap in the recorded data.

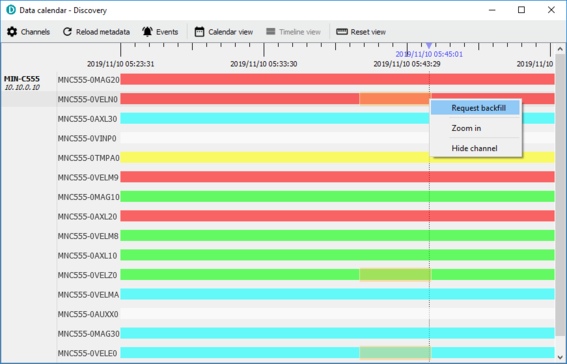

Use the mouse-wheel scrolling (or track- / touch-pad scrolling on a laptop) or highlight a portion of data, right-click and select “Zoom in” to zoom into the data. Multiple channel are selectable using key  .

.

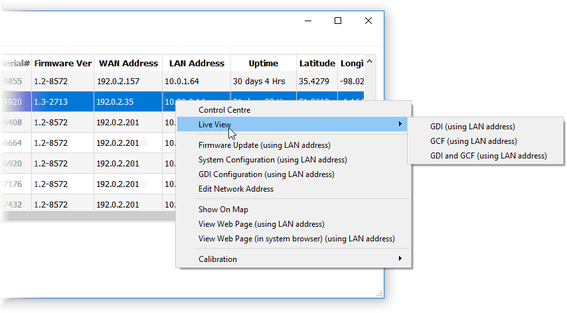

In Discovery, right-click on the Minimus of interest and select “Live View” → “GDI” to open a data viewer window. Select the streams that are going to be backfilled with recorded data.

In the calendar window select the portion of data to backfill into the viewer. Right-click and select “Request backfill”.

The requested data are automatically imported in the GDI data viewer in Discovery.

Note: The time required to upload the data depends on the window duration and the sample rate. Subsequent requests are queued and a new one is served once the previous one is completed.

5.9 Data transmission

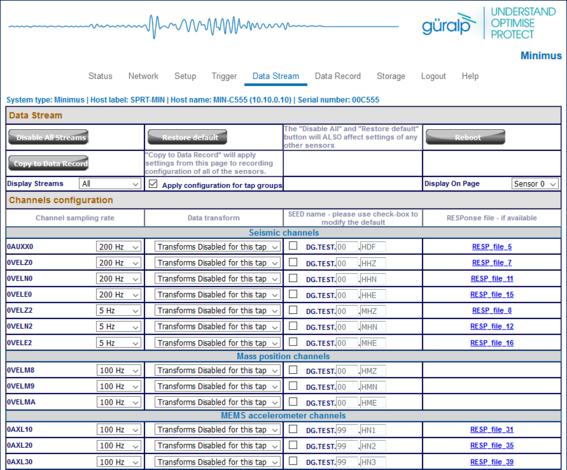

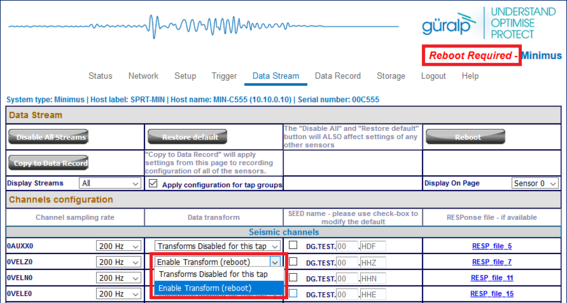

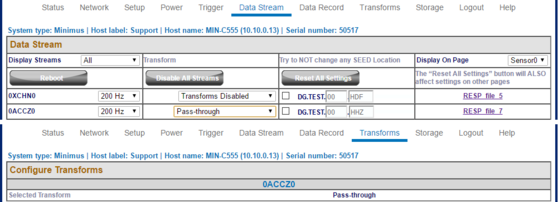

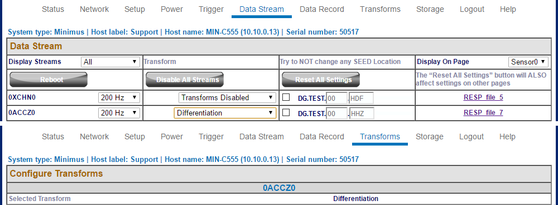

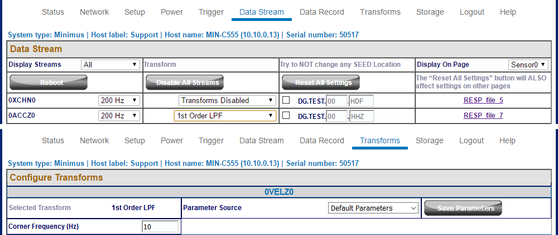

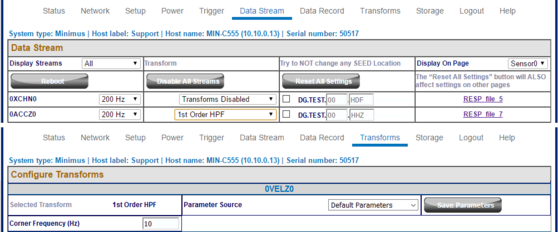

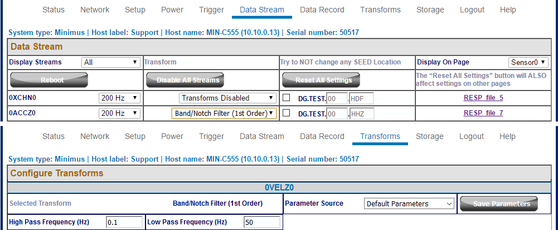

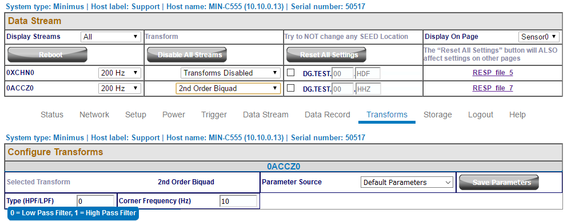

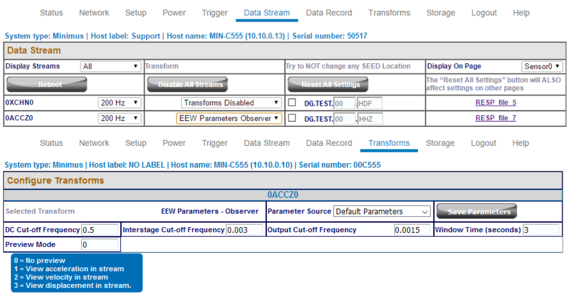

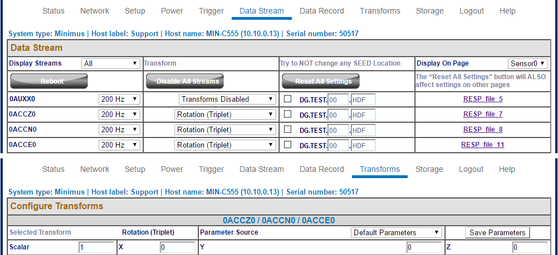

The monitoring and configuration of transmitted data is handled using the “Data Stream” tab of the instrument’s web page.

This page allows to configure the transmitted channels for each of the connected instruments and sensors internal to the Minimus.

The names and contents of each channel are described in Section 8.

Note: When changing a setting in the Minimus web page, ensure that you wait until the page refreshes before changing another setting. This allows time for the previous change to take effect.

The drop-down box at the top-left of the page named “Display Streams” filters out visible channels among Enabled and Disabled. The option “Apply configuration for tap groups” automatically apply the same configuration to three streams that belong to the same tap, e.g. 0VELZ0, 0VELN0, 0VELE0. The drop-down box at the top-right of the page named “Display On Page” allows to move from different instruments, e.g. Sensor 1.

The page is divided in four columns:

in most-left column, drop-down boxes are available for each channel to either select a sample rate or to exclude the channel from streaming (by selecting the “Disabled” option). All streaming can be stopped by clicking the

button. Same configuration can be applied to recorded channels by clicking the

button. Same configuration can be applied to recorded channels by clicking the  button. Default channel configuration can be applied by clicking the

button. Default channel configuration can be applied by clicking the  button.

button.in second column from the left, drop-down boxes are available for each channel to enable/disable transforms and, once transform is enabled, to select the transform to apply (see Section 5.15);

in third column from left, Location and Channel SEED codes can be configured. Cells are greyed out by default (default values applied) and they can be edited by clicking on the check-box;

in most-right column contains links to the RESP files associated to each of the seismic channels (see Section 5.12.5).

Upon changing the sample rate, enabling a transform or changing Location and Channels codes, the Minimus will need to be restarted for the changes to come into effect; this can be done by pressing the  button.

button.

During the reboot, the LEDs will flash, displaying the starting-up sequence (see Section 3.1.1) and the instrument web page will display the following screen.

Once the Minimus has successfully restarted, the full web browser display and controls will be available for use again.

5.9.1 Scream! (GCF format + Scream protocol)

The Minimus can act as a Scream! Server and stream data by sending GCF (Güralp Compressed Format) packets over a network connection using the scream data-transmission protocol.

This is primarily intended to support Güralp’s Scream! Software (see Section 4.3.2) or any software that can communicate using the Scream! Protocol, including Earthworm.

These include:

Güralp instruments with embedded acquisition modules (e.g. 40TDE)

Güralp DM24 and CD24 digitisers with embedded acquisition modules (e.g. Güralp DM24SxEAM[U])

Güralp Affinity digitiser

Network Acquisition Module (Güralp NAM)

Note: Güralp devices running the Platinum software can receive GCF data over the Scream protocol, but the GDI-link protocol is preferred in these cases.

5.9.2 GDI-link protocol

The Minimus can transmit data using the GDI-link protocol. GDI-link can currently be used with:

Güralp instruments with embedded acquisition modules (e.g. 40TDE)

Güralp DM24 and CD24 digitisers with embedded acquisition modules (e.g. Güralp DM24SxEAM[U])

Güralp Affinity digitisers

Güralp NAM (Network Acquisition Module)

Earthworm software (www.isti.com/products/earthworm/)

GDI-link supports both data push and pull from/to the Minimus. See Section 5.5 to configure data push to one or more remote clients, e.g. NAM.

GDI-link provides a highly efficient, low latency method of exchanging data via TCP between seismic stations and data centres. The protocol allows state-of-health information to be attached to samples during transmission. The topology can be many-to-one or one-to many. This means that a receiver can accept data from multiple transmitters and a single transmitter can send data to multiple receivers, allowing maximum flexibility for configuring seismic networks. GDI-link streams data sample-by-sample (instead of assembling them into packets) to minimise transmission latency.

A significant advantage of GDI-link is that it has the ability to stream data pre-converted into real physical units instead of just as raw digitiser counts, obviating a requirement for receivers to be aware of calibration values.

For more information on GDI-link, please refer to Güralp manual SWA-RFC-GDIL.

5.9.3 SEEDlink protocol

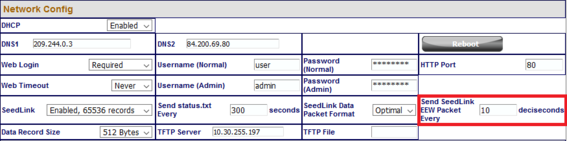

The Minimus can act as a SEEDlink server to send miniSEED data packets over a network connection. The SEEDlink server is enabled by default but it can be disabled and re-enabled if desired. The server has a configurable back-fill buffer.

Note: The Minimus SEEDlink back-fill implementation is packet-based.

In the “Network” tab of the Minimus' web page, select the desired SEEDlink mode:

The choices are:

“Enabled” - This is the normal operating mode. Choose between backfill buffer sizes of 2,048 records, 65,536 records or 139,264 records;

“Disabled” - turns off the SEEDlink server; and

“Debug” - this mode produces additional messages in the file seedlink.log which may be helpful if trying to diagnose a problem. It is available with backfill buffer sizes as before and, additionally, a 512-record buffer. (622,592 is listed but not implemented).

Note: As a general guide, we find that 139,264 records is normally sufficient to store around one day of triaxial, 100 sps data.

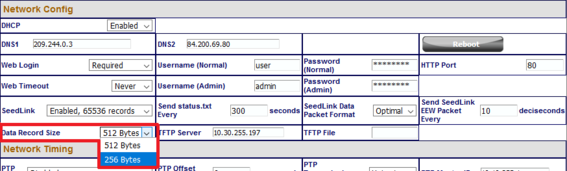

Standard SEEDlink has a fixed packet size of 512 Bytes and each miniSEED packet is completely populated with data before it is transmitted. The Minimus supports a modified version of SEEDlink that allows the transmission of incomplete packets. This improves latency.

Note: The modified SEEDlink is only available for EEW channels - i.e. the main seismic channels (generated with causal low latency filters) and the STA, LTA, STA/LTA ratio channels.

The user can specify the rate at which miniSEED packets must be transmitted. If populating complete packets would result in this rate not being achieved, incomplete packets are transmitted instead. The number of samples in each packet, therefore, depends both upon this setting and on the sample rate.

In the “Network” tab of the Minimus web page select the interval in deciseconds (1 decisecond = 100 ms or 0.1 seconds) between miniSEED packets (“Send SeedLink EEW Packets Every”).

The modified SEEDlink protocol also allows the use of 256-byte records as an alternative to the standard 512-byte format. The “Data Record Size” drop-down menu on the “Network” tab of the Minimus web page controls this behaviour.

Note: Not all SEEDlink clients can accept 256-byte records. Consult your client's documentation if in doubt.

To test the SEEDlink server, Güralp recommends using the slinktool software for Linux, which is distributed by IRIS. For more information and to download a copy, see http://ds.iris.edu/ds/nodes/dmc/software/downloads/slinktool/.

To show a list of available miniSEED streams, issue the command:

slinktool -Q IP-Address

Which produces output like the following:

DG TEST 00 CHZ D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

DG TEST 01 HHZ D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

DG TEST 00 CHN D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

DG TEST 01 HHN D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

DG TEST 00 CHE D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

DG TEST 01 HHE D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

DG TEST 00 MHZ D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

DG TEST 00 MHN D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

DG TEST 00 MHE D 2016-09-13 10:42:18 - 2016-09-13 10:46:56

⋮

To print miniSEED data records of a single channel, you will need the following command:

slinktool -p -S DG_TEST:00HNZ.D IP-Address

Which produces the following output:

DG_TEST_00_HNZ, 412 samples, 100 Hz, 2016,257,10:43:42.000000 (latency ~2.9 sec)

DG_TEST_00_HNZ, 415 samples, 100 Hz, 2016,257,10:43:46.120000 (latency ~2.6 sec)

DG_TEST_00_HNZ, 416 samples, 100 Hz, 2016,257,10:43:50.270000 (latency ~3.0 sec)

DG_TEST_00_HNZ, 413 samples, 100 Hz, 2016,257,10:43:54.430000 (latency ~2.6 sec)

DG_TEST_00_HNZ, 419 samples, 100 Hz, 2016,257,10:43:58.560000 (latency ~3.0 sec)

DG_TEST_00_HNZ, 418 samples, 100 Hz, 2016,257,10:44:02.750000 (latency ~2.6 sec)

DG_TEST_00_HNZ, 415 samples, 100 Hz, 2016,257,10:44:06.930000 (latency ~3.0 sec)

⋮

The SEEDlink server on the Minimus also supports the use of the “?” character as a wild-card within network, station and channel codes. This allows you to request multiple streams using a single command.

Note: Because the ? character has special meaning to the shell, it is safest to quote this character with a preceding backslash ('\') when used in command arguments.

5.9.3.1 MiniSEED extractor

The miniSEED extractor serves two purposes:

When an SD card is quick-formatted, each file is marked as unused but previously recorded data can still remain in them. Subsequent recordings overwrite these files from the beginning but, if the previous recording had a longer duration, old data will remain in the files. When the files are copied from the SD card to a PC, these older data can cause problems.

The format used on the SD cards consists of fixed-length, 128 MiB files. Some recordings might not use all of this space. When the files are copied from the SD card to a PC, this can cause wasted disk space.

The miniSEED extractor reads miniSEED files on the PC and copies them to a selected Destination folder, keeping track of the latest block time-stamp as it goes. If it encounters either an unused block or a time-stamp which is earlier than the previous one, it stops copying, truncating the output file at that point. This guarantees that each output file contains only blocks in time order and contains no wasted space.

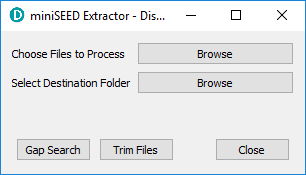

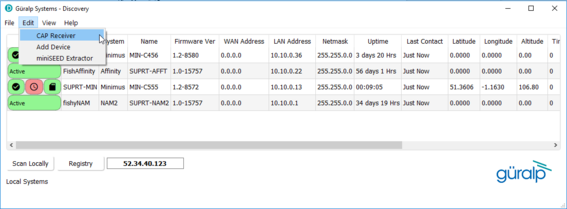

To use the tool, select "miniSEED Extractor" from the Edit menu. Click the first  button to select which files you wish to process and then the second

button to select which files you wish to process and then the second  button to select the folder into which you wish the output files to be written. Finally, click the

button to select the folder into which you wish the output files to be written. Finally, click the  button to extract the valid data from the selected files into new files in the selected destination folder.

button to extract the valid data from the selected files into new files in the selected destination folder.

The same tool can also generate a report of any gaps in the data from the input files. To use, select the input files as before and then click  to view the report.

to view the report.

5.10 Synchronisation of the sample-clock

The Minimus system synchronises its sample clock using an attached GNSS receiver or, if that is not available, Precision Time Protocol (PTP).

The currently supported GNSS systems are Navstar (GPS), GLONASS, BeiDou and Galileo.

Note: The GNSS can use only three different types of satellites simultaneously and GPS is always used, if available. The other two spots available can be either GLONASS, BeiDou or Galileo.

If visibility of the satellite constellation is available, this is the most accurate way to synchronise your digitiser. The Minimus accessory pack includes a combined GNSS antenna and receiver for this purpose: see Section 3.2.2 for details.

5.10.1 GNSS lock status

This is available in the “Status” tab of the instrument’s web page.

A number of GNSS reporting parameters are given, including:

Connection status

Last GNSS update (sync) & last GNSS lock date/time

GNSS Stability:

0% = no receiver connected;

1% = receiver connected, but waking up (this can occur if the GNSS receiver has been moved a long distance since last power-up).

2-99% = view of sky obstructed.

100% = normal operation with clear view of sky

Latitude, longitude, altitude

Horizontal dilution of precision (quality of satellite fix due to position of satellites relative to receiver)

GNSS PPS status

GNSS NMEA streaming

GNSS lock state (2D/3D)

Number of available satellites (in use / in view)

5.10.2 PTP (Precision Time Protocol)

The Minimus system supports timing provided through PTP.

The IEEE 1588 Precision Time Protocol (PTP) is a network protocol which uses modified network hardware to accurately time-stamp each PTP packet on the network at the time of transmission, rather than at the time that the packet was assembled. If you do not have an existing PTP infrastructure, the simplest way to use PTP is to add a "grand-master clock" to the same network segment as the digitisers. A typical such clock is the Omicron OTMC 100, which has an integrated GNSS antenna and receiver which it uses as its own synchronisation source. PTP timing can be extended over up to 100 metres of Ethernet cable or longer distances when fibre-optic cable is used. PTP is significantly more accurate than NTP but generally requires specialised hardware support.

In the “Status” tab of the Minimus web page, a number of reporting parameters are given, including:

PTP state

Last PTP time-stamp and last PTP lock date/time

PTP Stability:

Standby ⇒ PTP is running but timing is provided by GNSS;

No Master ⇒ PTP not available;

1-100% ⇒ PTP locking process indicator. 100% indicates a time accuracy of better than 200 ns.

Master IPv4 address

Master clock class and accuracy

Master time source

Network path delay

Network jitter estimate: quality indicator

Network outliers

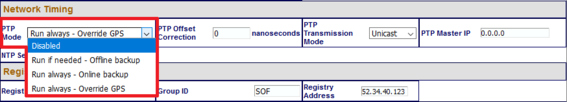

Under the heading “Network config” are four options:

Disabled ⇒ PTP is never used (default settings).

Run if needed – Offline backup ⇒ PTP is automatically enabled whenever the GNSS signal is lost. It is disabled while GNSS is available. This mode is used to minimise network traffic when GNSS is the primary timing source.

Run always – Online backup ⇒ PTP is always running but GNSS is used as the primary timing source. This mode is useful for faster fall-back from GNSS to PTP timing and for validation that PTP is available.

Run always – Override GPS = PTP is always running and takes priority over GNSS. This mode is useful in a system where PTP is the primary timing source, but GNSS may occasionally be connected for validation purposes.

PTP can be configured for multicast or unicast mode. In unicast mode, the server I.P. address must be specified. This is available in the “Network” tab of the digitiser’s web page.

5.10.2.1 Special notes for PTP with Maris ocean-bottom systems.

PTP is the only source of timing available for a deployed Maris digitiser. To configure, visit the “Network” tab of the digitiser web page.

If your PTP infrastructure produces a fixed offset (when compared with GNSS), a manual correction can be applied to compensate for this.

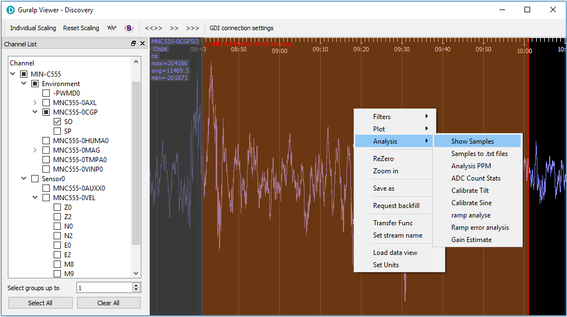

The required correction value can be extracted from the internal clock from GNSS stream of the Minimus. In the Live View enable the 0CGPSO channel and select at least 20 minutes of data. Right-click on the selection and click on Show Samples:

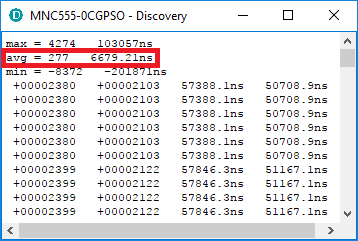

At the top of the resulting window, the maximum (max), average (avg) and minimum (min) values are displayed:

Note the value of the average, multiply by -1 and enter the resulting value in the PTP Offset Correction box in the Network Timing section of the Network web page.

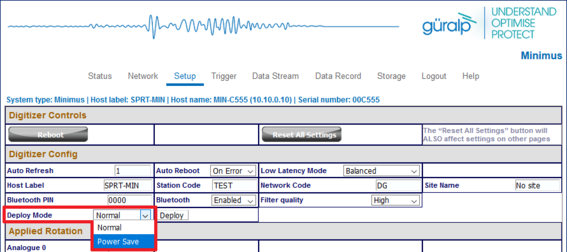

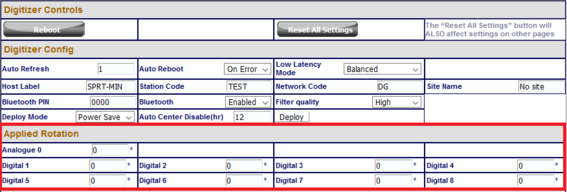

5.11 Deploy mode: Full power-save

The Minimus digitiser offers two deployment modes: "Normal" and "Power Save". "Full power-save" mode makes a number of configuration changes in order to reduce the unit's power consumption. This mode is particularly useful when using Maris digital ocean-bottom sensors.

The desired mode can be specified using the “Deploy mode” drop-down menu in the “Setup” tab of Minimus web page. Changes are not applied immediately.

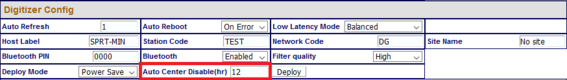

"Power Save" mode temporarily disables auto-centring of a connected the Maris digital sensor, so that it is not continually re-centring while being lowered to the sea floor. When this mode is selected, the “Auto Centre Disable (hr)” input field appears: use this to specify the length of time before auto-centring is re-enabled.

Note: Güralp recommend a value of 10 to 12 hours to fully cover the entire deployment procedure.

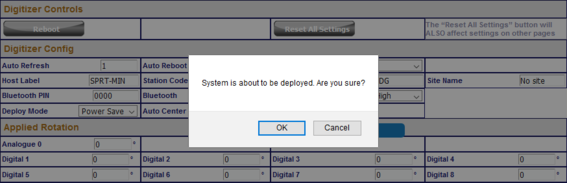

The final step is to click on the  button and confirm or cancel the operation from the pop-up window that appears.

button and confirm or cancel the operation from the pop-up window that appears.

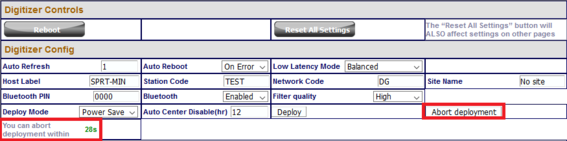

A thirty-second count-down will start before the system enters power-save mode. The screen changes and a new button is added:

You can cancel the operation before the countdown is complete by clicking the  button.

button.

Caution: The power-save mode will disable the Ethernet and GNSS modules. You will not be able to continue to use the web interface.

Once in deploy mode, the only way to re-enable the Ethernet module is to connect to the Minimus via a serial connection (see Section 7) or to use the GüVü Bluetooth app (see Section 6.4).

When a serial or Bluetooth connection is established, type the command powersave off in the console to disable the "Full power-save" mode and re-enable Ethernet communication.

5.12 Configuration and control of connected analogue instruments

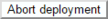

5.12.1 Setting instrument type

The analogue sensor type is user-selectable and the Minimus includes a choice of several Güralp sensors and accelerometers. If the sensor is not in the list, select “Generic velocity” or “Generic acceleration”, according to the instrument's response.

A reboot is required after this change.

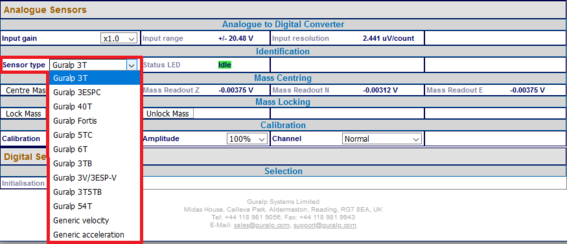

5.12.2 Setting instrument (sensor) gain for Güralp Fortis

The Güralp Fortis strong-motion accelerometer features a remotely-switchable gain option that can be controlled from inside Discovery. First, ensure that the physical gain switch on the underside of the Fortis is set to position “3” (as indicated by the engraving). See MAN-FOR-0001 for more details.

To change the gain electronically, first, set the “Instrument Type” to “Güralp Fortis”. Setting this option will then enable the “Instrument Gain” control. Under the “Instrument Gain”, select a gain setting (options: ±0.5g; ±1g; ±2g; ±4g).

Setting the instrument type to “Fortis” will also change the miniSEED channel names to indicate that data are recorded from an accelerometer, e.g. “HNZ”.

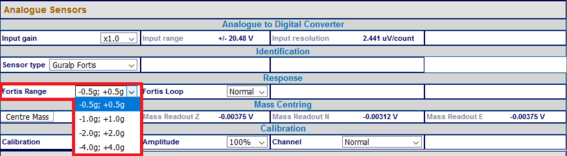

5.12.3 Setting digitiser gain

The input gain can be controlled from the "Setup" tab of the web page using the “Input Gain” drop-down box. Digitiser gain options available are: Unity, ×2, ×4, ×8 and ×12.

The input range and resolution change automatically when the gain is selected and the gain in the RESP files and Dataless SEED is updated automatically.

5.12.4 Mass control

The Minimus can lock, unlock and centre the masses of connected instruments.

5.12.4.1 Mass centring

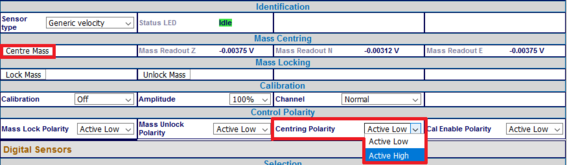

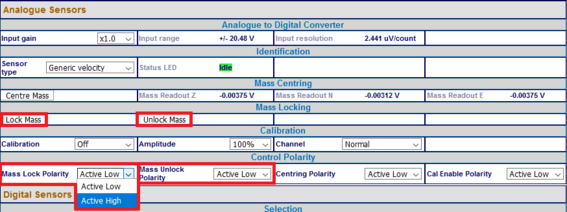

Many broadband seismometers (e.g. Güralp 3T and 3ESPC) support remote/electronic mass centring. Change the polarity of the control signal using the drop-down menu if necessary.

Mass centring can be controlled from the "Setup" tab of the web page using the  button. Mass centring status and control can also be found in the Centring tab of the instrument Control Centre window.

button. Mass centring status and control can also be found in the Centring tab of the instrument Control Centre window.

5.12.4.2 Mass locking

Some seismometers require their masses to be locked for transportation. Mass locking can be controlled from the "Setup" tab of the web page using the  and

and  buttons. Change the polarity of the control signals using the drop-down menu, if necessary.

buttons. Change the polarity of the control signals using the drop-down menu, if necessary.

Note: The mass lock control buttons are not displayed unless the selected sensor type has a mass-locking mechanism.

5.12.5 Instrument response parameters

Calibration is a procedure used to verify or measure the frequency response and sensitivity of a sensor. It establishes the relationship between actual ground motion and the corresponding output voltage. Calibration values, or response parameters, are the results of such procedures.

Response parameters typically consist of a sensitivity or "gain", measured at some specified frequency, and a set of poles and zeros for the transfer function that expresses the frequency response of the sensor. A full discussion of poles and zeros is beyond the scope of this manual.

The gain for a seismometer is traditionally expressed in volts per ms-1 and, for an accelerometer, in volts per ms-2. Other instruments may use different units: an electronic thermometer might characterise its output in mV per °C.

A calibration procedure is also used to establish the relationship between the input voltage that a digitiser sees and the output, in counts, that it produces. The results are traditionally expressed in volts per count. Each Minimus is programmed at the factory so that it knows its own calibration values.

Although the Minimus automatically receives calibration parameters from connected digital instruments (e.g. Güralp Radian), calibration values need to be entered manually for connected analogue sensors (e.g. Güralp Fortis).

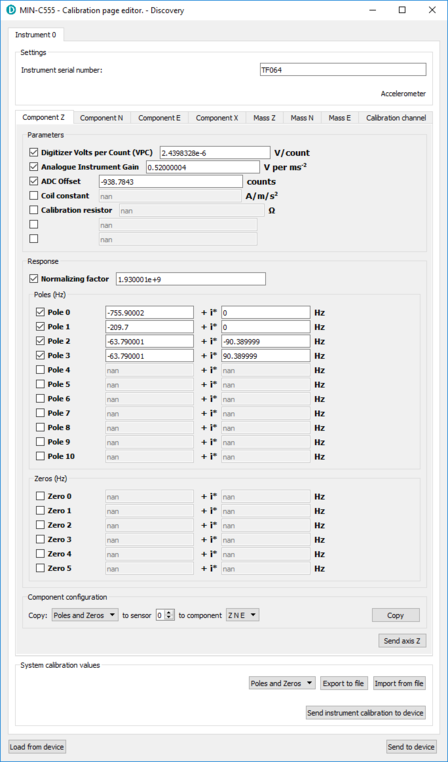

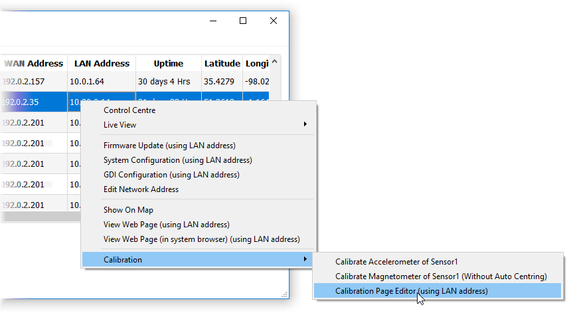

To enter the calibration values for your analogue instruments, right-click the Minimus in Discovery’s main window and select “Calibration” → “Calibration Editor”.

This form has one tab for each seismic component, for the mass positions and calibration channel. The instrument's response values should be entered in the here. These are:

The Digitiser Volts per Count (VPC) – the ratio between the input voltage and the digitised output value (“counts”). This field will be populated automatically with the correct value for this input channel of the Minimus.

Analogue Instrument Gain – this specifies the output voltage of the seismometer per unit of ground motion, as measured at 1 Hertz. This information is normally provided on a calibration document that is shipped with the instrument.

The ADC offset is the quiescent output seen when digitiser input is zero. This field will be populated automatically with the correct value for this input channel of the Minimus.

The Coil constant is the coil constant for the component being calibrated, in A/ms-2, as given on the analogue sensor calibration sheet.

The Calibration resistor is the value of the calibration resistor, in Ω, as given on the sensor calibration sheet. This is common to all sensor components.

The Normalising factor specifies the value that the transfer function (as specified by the poles and zeros) must be multiplied by in order to provide unity gain at 1 Hz.

The Poles and Zeros describe the frequency and phase response of the component. They must be specified in Hertz. This information is normally provided on a calibration document that is shipped with the instrument.

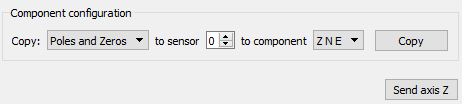

The calibration parameters for one component can be copied to any other component of the same instrument, or other instruments. This is especially useful for poles and zeros, because they are typically identical for all three components of all instruments in a class.

The drop-down menu in the “Component configuration” section allows selection of what to copy: poles and zeros, gains or everything. The destination sensor and component(s) can be selected in the subsequent drop-down menus. Click on the  button to copy and paste the selected values. Finally click on

button to copy and paste the selected values. Finally click on  button to send the calibration values to the digitiser and save them permanently. Repeat this last step for the other axis. Note that

button to send the calibration values to the digitiser and save them permanently. Repeat this last step for the other axis. Note that  only sends the calibration of the selected axis.

only sends the calibration of the selected axis.

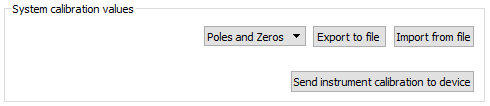

The overall system calibration parameters can be exported and saved in a file for future use by clicking on the  button under “System calibration values”.

button under “System calibration values”.

The resulting file-name will have the extension .conf. Values from an existing calibration file can be imported using the  button. The associated drop-down menu allows specification of what to import: poles and zeros, gains or everything. Click on

button. The associated drop-down menu allows specification of what to import: poles and zeros, gains or everything. Click on  to send the calibration values to the digitiser and save them permanently. Note that this action will only send the calibration of the selected sensor. Click on the

to send the calibration values to the digitiser and save them permanently. Note that this action will only send the calibration of the selected sensor. Click on the  button to send the complete calibration to the digitiser.

button to send the complete calibration to the digitiser.

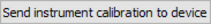

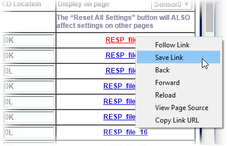

When transmitting MiniSEED data, the responses of the instruments and digitisers are encoded in a message called a “Dataless SEED” volume. The contents of these volumes can be displayed in human-readable form, known as RESP, by clicking on the “RESP file” link of each channel in the “Data Stream” and “Data Record” tab of the Minimus web page.

Clicking on a RESP file link produces a page like this:

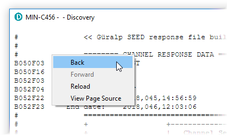

Right-click anywhere and select “Back” to return to the Minimus web page.

To save a RESP file, right click on it in the main list and select "Save Link":

Note: RESP files are not available for channels that have a transform enabled. For details about transforms, see section 5.15.

5.13 Configuration and control of connected digital instruments

Please refer to MAN-RAD-0001 for full details on configuring and controlling compatible digital instruments, such as the Güralp Radian, connected to the Minimus.

5.14 Setting sensor orientation and depth parameters

5.14.1 Applied rotation

A Matlab extension for Scream! allows easy determination of the exact orientation of a sensor relative to a surface reference sensor (which can be accurately aligned magnetically or geographically. The procedure is explained at https://www.guralp.com/howtos/determining-sensor-orientation.

The Relative Orientation extension of Scream! provides a correction angle that can be entered into the Sensor Orientation section of the Setup tab of the Minimus web page.

This feature can be applied to analogue seismometers and accelerometers and also to Borehole or Post-hole Radians, when installed with a vertical orientation.

Note: The input rotation is automatically applied to both transmitted and recorded data.

5.14.2 Instrument installation parameters

The Dip (tilt angle from vertical), Azimuth (tilt direction from North) and Depth of analogue or digital sensors connected to the Minimus can be set in the Setup tab of the web interface in the section “Instrument Installation Parameters”. The instrument to which the displayed parameters apply is selected using the drop-down menu.

Note: The orientation and depth are not applied to the data, the parameters are only saved in the Dataless SEED.

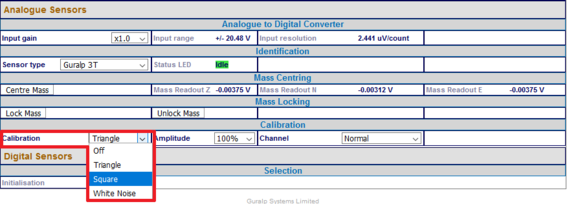

5.14.3 Inject a calibration signal

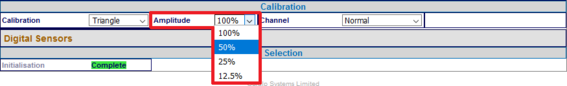

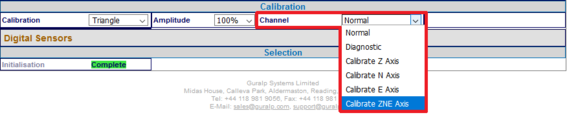

To check whether the analogue sensor(s) connected to the Minimus is correctly calibrated, go to the Setup tab of the web page and use the drop-down menu to choose between Triangle, Square and White Noise signal to be injected into the sensor's feedback loop.

Adjust the calibration signal amplitude at 100%, 50%, 25% or 12.5% of the DAC full range.

Finally, enable the calibration on all three components of the selected analogue sensor.

Note: The calibration channel, named nVELC0 (or nACCC0), produces an output if and only if the calibration is in progress.

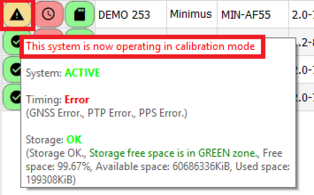

While the calibration is in progress, the webpage shows the warning message  and Discovery flags the status icon in yellow.

and Discovery flags the status icon in yellow.

5.15 Transforms

The Minimus is capable of applying mathematical transforms to the streamed and recorded data. These include low-pass and high-pass filters, integration, differentiation, rotation, STA/LTA ratio etc.

When a specific transform is activated on a particular channel, the resulting streamed (or recorded, accordingly to the chosen configuration) data output is automatically transmitted and/or recorded with the transform applied. The units-of-measure are re-calculated accordingly.

Transform functions are enabled or disabled from the “Data Stream” and “Data Record” tabs for each channel.

Note: To enable or disable a transform on any channel, it is necessary to reboot the Minimus. Transforms can be applied only on enabled channels.

Pass-through – see Section 5.15.1;

2nd order bi-quadratic filter – see Section 5.15.6;

1st order low-pass filter – see Section 5.15.3;

1st order high-pass filter – see Section 5.15.4;

1st order band/Notch filter – see Section 5.15.11;

STA/LTA ratio – see Section 5.15.10;

Integration – see Section 5.15.7;

Double integration – see Section 5.15.8;

Three-dimensional rotation – see Section 5.15.11;

EEW parameters – Observer – see Section 5.15.9;

Differentiation – see Section 5.15.2;

QSCDx sender – see Section 5.15.12;

MMA logger – see Section 5.15.13.

Some transforms require parameters such as frequencies or coefficients. For these, the user can either use a fixed, default set, or create their own custom set.

To use customised parameters, visit the “Transform” tab and select the “Saved User Parameters” option in the “Parameter Source” drop-down menu. Type in the required parameters and then click  to store them. It is possible to switch between Default and Saved User Parameters without altering the stored custom parameters but clicking

to store them. It is possible to switch between Default and Saved User Parameters without altering the stored custom parameters but clicking  while “Default parameters” is selected will overwrite the customised parameters with the default values.

while “Default parameters” is selected will overwrite the customised parameters with the default values.

The various transforms are each described in the following sections.

Caution: The  button at the top of the "Transform" column does not disable transforms for all streams. It stops transmission of all streams, which may not be what you intend.

button at the top of the "Transform" column does not disable transforms for all streams. It stops transmission of all streams, which may not be what you intend.

5.15.1 Pass-through

This null transform simply outputs a copy of the input data, without applying any transform. It has no configuration parameters.

Note: This transform is selected by default when transforms are first enabled or when an invalid transform is selected. Do not use pass-through as a method of disabling transforms: instead, select "Disable transforms" from the drop-down menu next to each stream on the "Data Streams" tab,

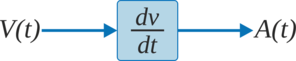

5.15.2 Differentiation

This transform differentiates the input data, e.g. if the input is a velocity (ms-1) channel, the output will be acceleration (ms-2). It has no configuration parameters.

5.15.3 1st order LPF

This transform applies a first-order low-pass filter to the input data.

The single configurable parameter is "Corner Frequency": this specifies, in Hz, the frequency at which the output power is attenuated by -3 dB. Above this frequency, output power is attenuated by a further 6 dB per octave or 20 dB per decade.

5.15.4 1st Order HPF

This transform applies a first-order high pass filter to the input data.

The output is the difference between a low-pass filtered copy of the signal and the unfiltered signal.

The single configurable parameter is "Corner Frequency": this specifies, in Hz, the frequency at which the output power is attenuated by -3 dB. Below this frequency, output power is attenuated by a further 6 dB per octave or 20 dB per decade.

Note: The high-pass filter is implemented by subtracting the output of a low-pass filter from the unfiltered data:

5.15.5 1st Order Band/Notch filter

This transform applies first-order band stop or Notch filter to the input data.

The band-stop filter is implemented as a configurable chain of two components:

A 1st order high pass filter (implemented using an LPF and a subtractor, as described in Section 5.15.4), to gradually attenuate low-frequency integrator drift.

A 1st order low pass filter (implemented as described in Section 5.15.3).

The configurable parameters are the "High Pass Frequency" (HPF corner frequency as defined in Section 5.15.4) and the “Low Pass Frequency” (LPF corner frequency as defined in Section 5.15.3).

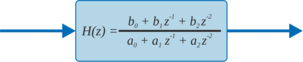

5.15.6 2nd Order biquad

This transform applies a second-order bi-quadratic filter to the input data.

The biquad filter is a second-order recursive linear filter, containing two poles and two zeros. In the Z-plane, the transfer function is the ratio of two quadratics in z, as shown.

The two configurable parameters are:

"Corner Frequency": this specifies, in Hertz, the frequency at which the output power is attenuated by -3 dB; and

"Type":

0: low-pass mode; and

1: high-pass mode.

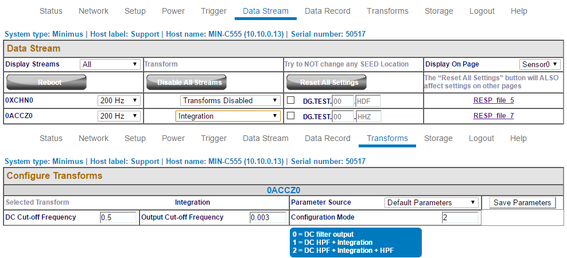

5.15.7 Integration

This transform integrates the input data, e.g. if the selected channel unit is velocity (ms-1), the output produced is displacement (m).

The integration transform is implemented as a configurable chain of three components:

A DC filter (2nd order high-pass bi-quadratic) removes any DC component, which would cause the output to grow without limit;

The integrator itself; and

A 1st order high pass filter (implemented using an LPF and a sub-tractor, as described in Section 5.15.4), to gradually attenuate low-frequency integrator drift.

The configurable parameters are:

"DC Cut-off Frequency": this specifies the -3 dB point (in Hertz) for the initial high-pass filter;

"Output Cut-off Frequency": this specifies the -3 dB point (in Hertz) for the output high-pass filter;

“Configuration Mode”, which configures how many elements of the chain are used. The options are:

Apply only the initial DC filter;

Apply the DC filter and the integrator; and

Apply the DC filter, the integrator and the output HPF.

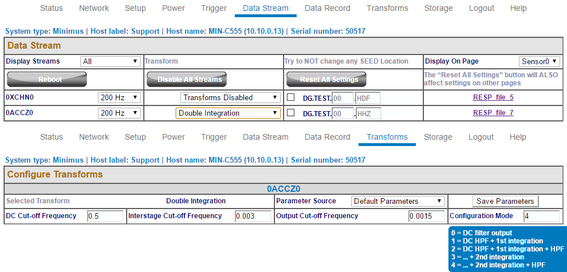

5.15.8 Double Integration

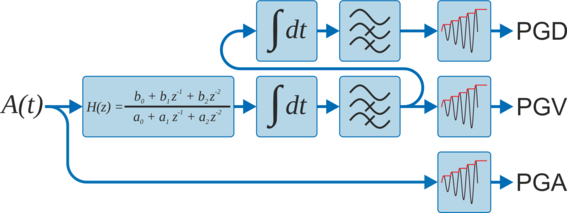

This transform integrates the input data twice so, for example, if the selected channel is acceleration (ms-2), the output produced is displacement (m).

Analogously to the single integrator, the double integrator applies an initial DC high-pass filter and then two further high-pass filters, one at the output of each integrator. The high-pass filters are implemented using an LPF and a subtractor, as described in Section 5.15.4.

The configurable parameters are:

"DC Cut-off Frequency": this specifies the -3 dB point (in Hertz) for the initial high-pass filter;

"Interstage Cut-off Frequency": this specifies the -3 dB point (in Hertz) for the first integrator output high-pass filter;

"Output Cut-off Frequency": this specifies the -3 dB (in Hertz) point for the second integrator output high-pass filter;

“Configuration Mode”, which configures how many elements of the chain are used. The options are:

Apply only the initial DC filter;

Apply DC filter and first integrator;

Apply DC filter, first integrator and interstage HPF;

Apply DC filter, first integrator, interstage HPF and second integrator; and

Apply DC filter, first integrator, interstage HPF, second integrator and second output HPF.

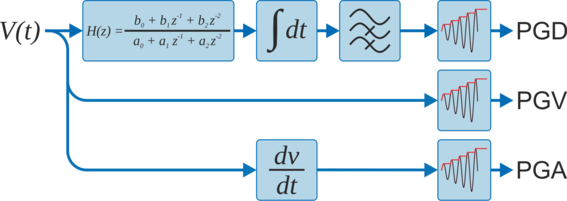

5.15.9 EEW Parameters – Observer

When an EEW trigger occurs (or is simulated – see below), the peak ground motion values (Peak Ground Acceleration (PGA), Peak Ground Velocity (PGV) and Peak Ground Displacement (PGD)) are calculated and automatically recorded over the selected time-window and subsequently transmitted as a CAP message (see Section 5.16 for more details). This transform allows the operator to directly observe the acceleration, velocity and displacement output on the real-time streams. It is available for use with both velocity and acceleration input signals.

Note: The EEW parameter transform can work as an observer: doesn’t necessarily modify the data streams on which it is applied.

The implementation of the transform differs, depending on whether the input stream represents velocity or acceleration data.

The high-pass filters are implemented using an LPF and a subtracter, as described in Section 5.15.4.

The configurable parameters are:

"DC Cut-off Frequency": this specifies the -3 dB point (in Hertz) for the initial high-pass filter;

"Interstage Cut-off Frequency": this specifies the -3 dB point (in Hertz) for the first integrator output high-pass filter. This is only used when the input signal is acceleration;

"Output Cut-off Frequency": this specifies the -3 dB (in Hertz) point for the sole (velocity input) or final (acceleration input) integrator output high-pass filter;

"Window time": this specifies the duration, in seconds, of the time-window over which the peak values are reported;

“Preview Mode”: the values to be shown in the output stream:

unmodified original stream (acceleration or velocity);

acceleration;

velocity; or

displacement.

Note: Güralp recommend using the integration (section 5.15.7) and double integration (section 5.15.8) transforms to test the filter parameters, because the effect of the parameters will then be clearly visible in the transformed streams. Once suitable parameters have been determined, they can be copied to the EEW Parameter - Observer transform.

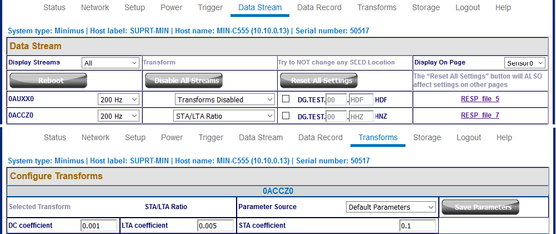

5.15.10 STA/LTA Ratio

The Earthquake Early Warning system (EEW) compares the ratio of a short-term average (STA) to a long-term average (LTA) in order to detect "trigger" conditions. For more information see Section 5.16.

This transform is included to help determine parameters for configuring the EEW system. It does not affect the operation of the EEW system in any way. The transform calculates the ratio between the result of the Short Term Average filter and the Long Term Average filter. The input signal is passed through a high-pass filter which removes any DC offset.

The configurable parameters are:

"DC Frequency (Hz)": this specifies the corner frequency (-3 dB point) in Hertz for the initial high-pass filter;

"LTA Period (seconds)": this is the Short Term Average filter time period (the reciprocal of the corner frequency);

"STA Period (seconds)": this is the Long Term Average filter time period (the reciprocal of the corner frequency);

“Trigger Threshold”: this is the STA/LTA ratio threshold value above which a trigger will occur;

“Event Window (Seconds)”: this is the duration of the event after the STA/LTA trigger occurs; any subsequent threshold crossing within this period is treated as belonging to the same event. This can be used to avoid spurious false triggers.

“Initial Timeout (Seconds)”: this specifies an initial period of insensitivity after the trigger function is initialised or changed. This can be used to avoid spurious false triggers.

The high-pass filter is implemented using an LPF and a subtracter, as described in Section 5.15.4.

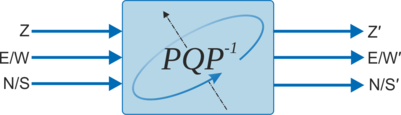

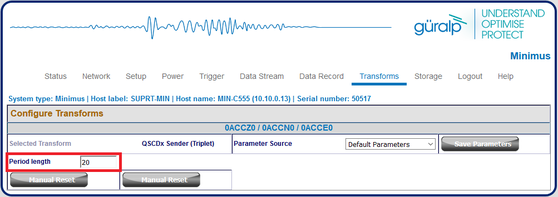

5.15.11 Three-dimensional Rotation

This transform rotates three velocity/acceleration seismic components in space. Rotations are represented by unit quaternions (in preference to the more usual Euler angles: yaw, pitch and roll) because they are unambiguous and avoid the problem of gimbal lock.

Note: The rotation transform can only be applied if it is enabled in all three velocity/acceleration components of a single instrument at the same sample rate.

Any rotation in three dimensional space can be represented as a combination of a unit three-dimensional vector, u⃗, which specifies the axis (and sense) of the rotation, and a scalar angle, θ, which specifies the amount of rotation

Güralp follows a North, East, Up convention when describing sensor orientation. Using this convention, we can represent u⃗ as [u,v,w] and use Pauli's extension to Euler's formula:

to form a quaternion:

where:

For example, a perfectly- oriented sensor has a (null) rotation of

, where the sensor's Z, N and E axes align with the North, East and Up global axes.

A rotation of

represents a sensor that has been rotated 90o about its x axis to align the sensor's Z, N and E axes with global North, Down and East respectively.

Note: Clockwise rotations, when looking along an axis, are denoted as positive. This is generally known as the "right-hand rule" because, if you point your right thumb along the (directed) axis, your fingers will curl in a clockwise direction about it.

Note: Clockwise rotations, when looking along an axis, are denoted as positive. This is generally known as the "right-hand rule" because, if you point your right thumb along the (directed) axis, your fingers will curl in a clockwise direction about it.

In the degenerate case of a simple rotation about a vertical axis (commonly used to correct data from a misaligned borehole instrument), the axis of rotation is vertical, so our unit vector is [0,0,1] (following the "North, East, Up" convention). To rotate by θ (where positive θ is clockwise when looking upwards), our quaternion should be:

As a final check, note that

which satisfies our requirement for a unit quaternion. The parameters to enter in the Configure Transforms fields are, therefore:

Scalar ⇒

, X ⇒ 0 , Y ⇒ 0 and Z ⇒

5.15.12 QSCD Sender (triplet)

The QSCD protocol (Quick Seismic Characteristic Data) transmits values computed from the three triaxial streams of an instrument. One packet is transmitted every second so the number of samples in each packet is equal to the sample rate of the three input streams.

QSCD calculations are implemented using transforms and configured via the Data Stream tab of the Minimus web page. The three input channels must all be configured with the QSCD (triplet) transform. (The transform is disabled if the sample rates of the input streams do not match.)

In the Transform tab, the parameter “Period length” configures the number of samples to include in a QSCD packet. For example, QSCD20 requires the sample rate of the streams to be 20 sps so the “Period length” must be set to 20 (samples), in order to send a packet every second.

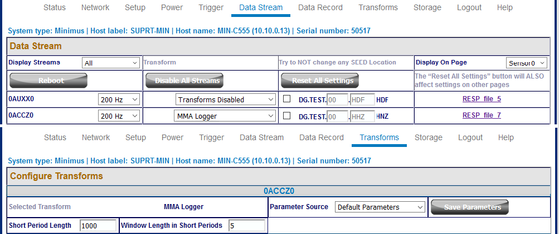

5.15.13 MMA Logger

The MMA logger transform is a function that periodically calculates and logs Maximum Minimum and mean (Average) values over a selected window of data.

Note: The EEW parameter transform is an observer: doesn’t modify the data streams on which it is applied.

The two configurable parameters are:

"Short Period Length": this is the length of time between logging events expressed in samples, e.g. 200 samples when applied to a tap configured at 100sps produces an MMA calculation and logging every 2 seconds.

“Window Length in Short Periods”: is the length of window over which the Max, Min and Average values are calculated, in terms of number of short periods.

5.16 Earthquake Early Warning

The “Trigger” tab is dedicated to Earthquake Early Warning settings. These are disabled by default because of the amount of processing resource – and hence, power – consumed by triggering calculations.

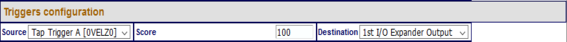

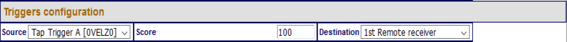

The Triggers section of the web page enables the user to configure the triggering system. The trigger Sources should be configured firstly because different configuration options are displayed for different source types. Once the source-specific settings are configured, the scores and destinations should be specified. Destinations can be shared between sources, allowing the creation of networks (directed graphs) of systems for distributed event detection.

The heart of the Earthquake Early Warning subsystem are the triggering algorithms: an STA/LTA (Short-Time-Average divided by Long-Time-Average) and level (threshold) algorithms.

The STA/LTA algorithm continuously calculates the average values of the absolute amplitude of a seismic signal in two simultaneous moving-time windows. The short time average (STA) is sensitive to seismic events while the long time average (LTA) provides information about the current amplitude of seismic background noise at the site. When the ratio of STA to LTA exceeds a pre-set threshold value an event is “declared”.

The threshold algorithm, instead, declares the presence of an event when the raw data in input passes above or below a pre-set threshold value.

5.16.1 Trigger sources

The available sources for the trigger are listed below, along with the configurable fields available in each case.

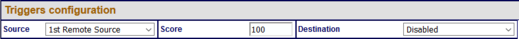

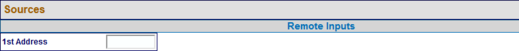

1st/2nd/3rd/4th Remote Source: This setting is used for multiple-source triggering networks. The sources specified here are other Minimus digitisers or Minimus based instruments, specified by the I.P. addresses configured in the “Remote Inputs” section:

The configurable fields in these cases are:

Score: this assigns a number of points to this trigger. The points value is used when assessing multiple-source triggers. This value is ignored when a trigger is not configured to use multiple sources.

Destination: this drop-down menu specifies the destination for the trigger. See Section 5.16.2 for more information.

nth Address: is the I.P. address of the remote source, e.g. another Minimus.

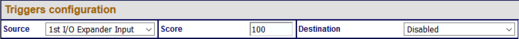

1st/2nd/3rd/4th I/O Expander Input: Select this value to use inputs from a connected Minimus 8 channel I/O Expander Module.

The configurable fields in these cases are:

Score: this assigns a number of points to this trigger. The points value is used when assessing multiple-source triggers. This value is ignored when a trigger is not configured to use multiple sources.

Destination: this drop-down menu specifies the destination for the trigger. See Section 5.16.2 for more information.

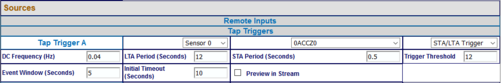

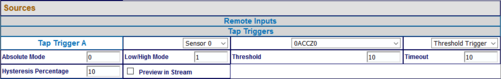

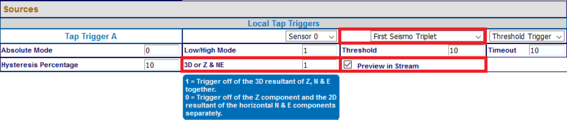

Tap Trigger N:: seismic or environmental Minimus channels selectable among any of the active taps in the “Data Stream” and “Data Record” tabs.

The configurable fields in these cases are:

Score: this assigns a number of points to this trigger. The points value is used when assessing multiple-source triggers. This value is ignored when a trigger is not configured to use multiple sources.

Destination: this drop-down menu specifies the destination for the trigger. See Section 5.16.2 for more information.

Sensor number: this drop-down menu selects what sensor’s streams to use as input of the trigger algorithm.

Tap: this drop-down menu select the stream to use as input of the trigger algorithm. The choice is between single taps, e.g. 0VELZ0, or triplets, e.g. First Seismo Triplet.

Trigger type: this drop-down menu chooses to use either STA/LTA or threshold algorithm.

The STA/LTA trigger algorithms includes the configuration of the following parameters:

“DC Frequency”: initial AC coupling HPF corner frequency;

“LTA Period”: Long Term Average filter time period (1/corner frequency);

“STA Period”: Short Term Average filter time period (1/corner frequency);

“Trigger Threshold”: STA/LTA ratio level at which trigger occurs;

“Event Window”: After an event has been detected, subsequent crossing of the STA/LTA ratio threshold within the defined event window are treated as part of the same event and, therefore, not considered as new trigger event;

“Initial Timeout”: period of inactivity after the trigger function is initialised in order to avoid false triggers.

The threshold trigger algorithms includes the configuration of the following parameters:

“Absolute Mode”: specifies if the threshold has to act on magnitude with sign (0) or absolute value of the signal (1).

“Low/High Mode”: defines whether the threshold is exceeded when the signal passes below it (0) or above it (1);

“Threshold”: value of the threshold expressed in native signal unit, e.g. m/s²;

“Timeout”: specifies the time to wait (in seconds), after the threshold crossing, before accepting a new event;

“Hysteresis Percentage”: defines the hysteresis point in terms of percentage of threshold value below or above threshold. The hysteresis point is below the threshold for High Mode, above the threshold for Low Mode.

The “Preview in Stream” box temporally shows (in the live streams) the output calculated by the trigger algorithm, e.g. the STA/LTA ratio. In the case ofan STA/LTA ratio trigger, when a single stream is selected as source, the calculated STA/LTA ratio is shown in place of the original data.

Note: Only STA/LTA ratio has preview on single streams, both Threshold and STA/LTA ratio have preview of triplets.

When a triplet is selected as source, “3D or Z & NE” parameters is used to choose what type of preview to visualise.

For STA/LTA ratio trigger algorithm:

0: shows STA/LTA ratio calculated on 2D resultant vector of N and E components. The 2D STA/LTA ratio is shown in place of original E/W component. Also, shows the STA/LTA ratio calculated on Z component and it is shown in place of original Z component. N/S component shows normal seismic output.

1: shows STA/LTA ratio calculated on 3D resultant vector of Z, N and E components. The STA/LTA ratio is shown on E/W component. Z and N/S components show normal seismic output.

For Threshold trigger algorithm:

0: shows the 2D resultant vector of N and E components. The 2D resultant is shown in place of E/W component. Z and N/S components show normal seismic output.

1: shows the 3D resultant vector of Z, N and E components. 3D resultant is shown in place of E/W component. Z and N/S components show normal seismic output.

5.16.2 Trigger destinations

The options available form the various Destination fields are:

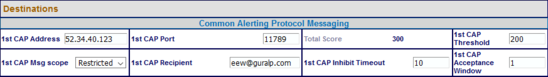

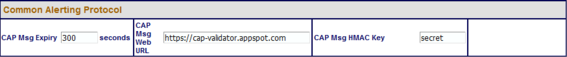

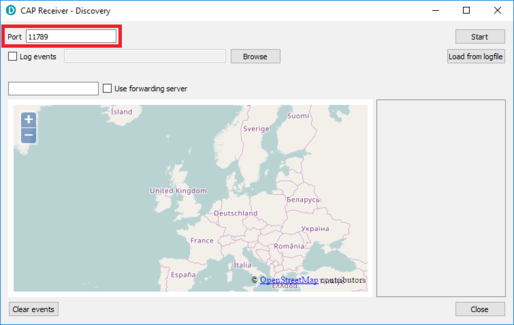

1st/2nd/3rd/4th CAP receiver: When a trigger is declared, the system will issue messages using the Common Alerting Protocol (for the full specification of this protocol, please refer to

https://docs.oasis-open.org/emergency/cap/v1.2/CAP-v1.2-os.html).This field selects to which of the four available CAP receivers the trigger information should be sent to.

Various parameters control how the CAP message is created:

nth CAP Address: the I.P. address or DNS name of the CAP receiver;

nth CAP Port: the UDP port on which the CAP receiver is listening;

Total Score: this is an information field, it displays an automatically-calculated total of the scores from all of the input sources that specify this destination;

nth CAP Threshold: this threshold is used when multiple input sources contribute to this trigger. Otherwise trigger threshold from source configuration is used.

nth CAP Msg scope: this value is copied to the “scope” field of the CAP message;

nth CAP Recipient: this value is copied to the “addresses” field of the CAP message;

nth CAP Inhibit Timeout: is the time the Minimus waits before sending new CAP message if a new event is detected after a previous CAP message was sent;

nth CAP Acceptance Window: subsequent source triggers for a given destination are counted towards the cumulative score if they arrive within this window;

CAP Msg Expiry: this parameter determines the value used to populate the optional “expires” field in the CAP message. If required, it should be specified in seconds.

CAP Msg Web URL: this parameter determines the value used to populate the optional “web” field in the CAP message. It should be a full, absolute URI for an HTML page or other text resource with additional or reference information regarding this alert.

CAP Msg HMAC Key: a shared key used for signing the CAP message. All CAP messages generated by Minimus are signed. The user should set this key to a private value. The HMAC digest can then be used to both authenticate the sender and validate the contents of CAP messages by anyone who is privy to the shared key. This prevents the generation of false, malicious CAP messages by a third party.

EEW parameters (PGA, PGV and PGD values) are sent in the CAP messages body if and only if the “EEW parameter – Observer” transform is enabled on the source taps (see Section 5.15.9).

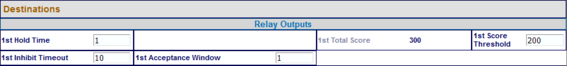

1st-8th I/O Expander Output: Select this value to use outputs from a connected Minimus 8 channel I/O Expander Module. See MAN-MIN-1001 for more details.

Various parameters control how the I/O Expander behaves:

nth Hold Time: is the relay switch timeout in seconds. If configured to 0: no timeout is used, otherwise relay will be released after specified number of seconds;

nth Total Score: this is an information field, it displays an automatically-calculated total of the scores from all of the input sources that specify this destination;

nth Score Threshold: this threshold is used when multiple input sources contribute to this trigger. Otherwise trigger threshold from source configuration is used;

nth Inhibit Timeout: is the time the Minimus waits before sending new command to the I/O Expander if a new event is detected after a previous command was sent;

nth Acceptance Window: subsequent source triggers for a given destination are counted towards the cumulative score if they arrive within this window.

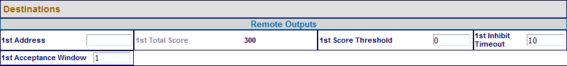

1st/2nd/3rd/4th Remote Source: This setting is used for multiple-destination triggering networks. The destinations specified here are other Minimus digitisers or Minimus based instruments, specified by the I.P. addresses configured in the “Remote Outputs” section:

nth Address: the I.P. address of the remote Minimus;

nth Total Score: this is an information field, it displays an automatically-calculated total of the scores from all of the input sources that specify this destination;

nth Score Threshold: this threshold is used when multiple input sources contribute to this trigger. Otherwise trigger threshold from source configuration is used.

nth CAP Inhibit Timeout: is the time the Minimus waits before sending new message if a new event is detected after a previous message was sent;

nth Acceptance Window: subsequent source triggers for a given destination are counted towards the cumulative score if they arrive within this window.

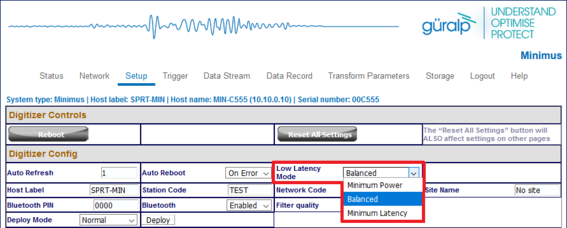

5.16.3 Low Latency Mode

In the “Setup” tab, the “Low Latency Mode” drop-down menu controls the processor workload that affects the power-consumption of the Minimus. This control can be used to prioritise power-consumption at the expense of latency, to balance the two or to optimise latency regardless of the power consumption. Three settings are available:

Minimum Power ⇒ slow processing / higher latency;

Balanced ⇒ optimal;

Minimum latency ⇒ fast processing / lower latency.

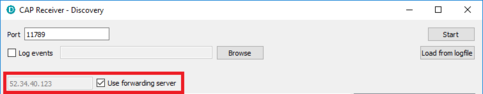

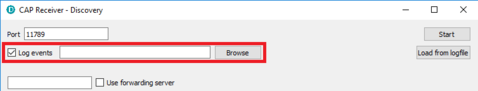

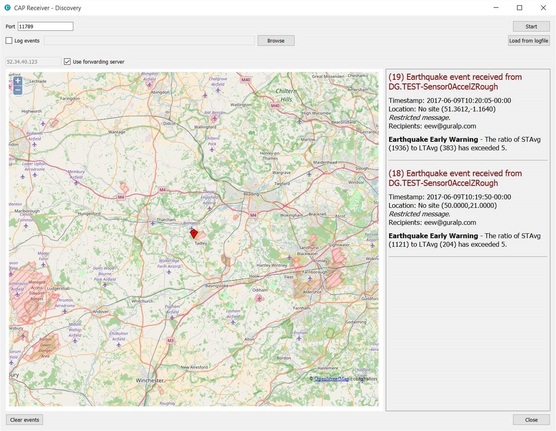

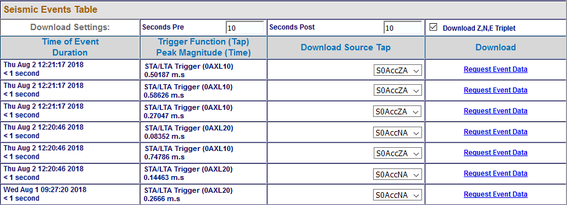

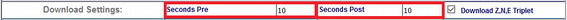

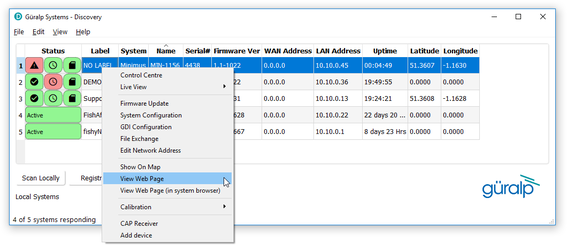

5.16.4 CAP receiver