Chapter 3. Installing the CMG-EDU

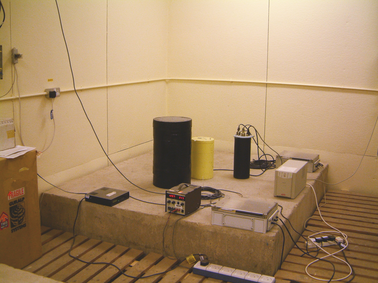

3.1 Installing in vaults

The CMG-EDU is a sensitive instrument designed to measure extremely small movements of the ground. These movements are the sum of all the vibrations arriving at the instrument: as well as distant earthquakes and nearby tremors, the ground responds to surf on nearby beaches, quarry blasts, heavy machinery, traffic, and even people moving around the building. Temperature changes and air currents in the same room as the sensor can also affect its output.

3.1.1 Choosing a location

When studying natural earth movements, any other effects introduce unwanted noise into the system. It is therefore important to choose an appropriate site for the instrument, ideally in an underground vault with the sensor installed on a concrete pier that is in direct contact with the bedrock.

This setup has a number of advantages:

It is installed below ground. Most man-made noise tends to travel along the surface, and natural microseisms (tiny natural flexings of the Earth's crust) also occur near the surface.

Good contact with bedrock means that the signals accurately reflect earth motions; seismic waves do not have to travel through layers of soft soil and sediment.

If the vault is inside a larger structure, its foundations are separated from the pier, so that nearby vibrations are not transmitted to the sensor.

A high-quality seismic vault can be incorporated into the construction plans of a new building at relatively low cost. However, if you are not in a position to build a dedicated vault, you can still reduce noise to a satisfactory level by

installing below ground, in the basement or sub-basement of an existing building;

placing the sensor directly on a cement floor to improve contact; and

locating the sensor in a quiet corner away from people and machinery (e.g. air-conditioning and heating systems, elevators, etc.)

Installation on higher floors is not recommended, especially for horizontal sensors, since any “give” in the floor near the sensor will cause it to tilt slightly and register a signal.

3.1.2 Temperature stability

The CMG-EDU can operate over a wide temperature range (–10 °C to +75 °C). However, the sensor mass is sensitive to fluctuations in local temperature. This affects the response of the instrument at long periods. Sunlight and other bright lights can also cause small mechanical stresses that will be detected by the sensor. You can minimise these effects by

installing in a basement, where the temperature is normally more stable than above ground;

locating the sensor in a dark, protected corner, and

enclosing it in an insulated box (expanded polystyrene works very well). This also helps protect the sensor from air currents.

3.1.3 Other considerations

The sensor and cables should be situated well away from other electical cables and appliances. Stray radiation from these sources may interfere with the sensor's electronics.

The sensor should be placed on a smooth, level surface free from cracks. Small cracks tend to open and close slightly with changes in humidity and temperature, causing the surface to move slightly.

All three of the sensor's metal feet must make good contact with the floor.

The signal cable from the sensor should rest loosely on the ground nearby, so that vibrations are not transmitted along it.

If your recording or digitizing equipment has front-panel indicators or connectors, make sure it can be reached without disturbing the sensor.

The GPS unit needs to be in a location where it can see as many satellites as possible. A location with a good view of the sky, preferably down to the horizon, is recommended. If you are in the Northern Hemisphere, make sure as much of the southern sky as possible is visible. Conversely, in the Southern Hemisphere, make sure the GPS can see a large area of sky to the north.

The GPS unit is supplied with a 15 m cable to the digitizer.

3.2 Setting up

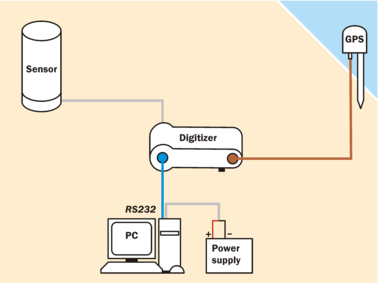

Once you have chosen suitable locations for the sensor, digitizer and GPS, you need only connect the various components and supply them with power. The digitizer and sensor will begin working immediately.

Connect the grey cable attached to the sensor to the SENSOR socket on the digitizer.

Connect the brown cable attached to the GPS unit to the GPS socket on the digitizer.

The remaining blue and grey cables are joined together at a 9-pin RS232 socket. Connect this socket to your PC’s serial connector.

The grey cable from the RS232 connector ends in red and black wires. Connect the black wire to the negative (–) terminal of the power supply, and the red wire to the positive (+) terminal.

The blue cable from the RS232 connector ends at a blue socket. Connect this to the DATA plug on the digitizer. Do this step last – an intermittent power supply can damage the digitizer, so it is best to make sure the wires to the power supply terminals are securely connected before you connect the digitizer.

When everything is connected, the digitizer should be drawing around 50 mA from the power supply. You can measure this either directly from the power supply unit (if it has the facility) or by connecting a 5 W-rated, 1 Ω resistor in series with the positive terminal and measuring the voltage drop across it: 50 mA through a 1 Ω resistor should consume 50 mV.

If the digitizer draws significantly more or less than 50 mA, switch it off immediately and contact Güralp Systems.